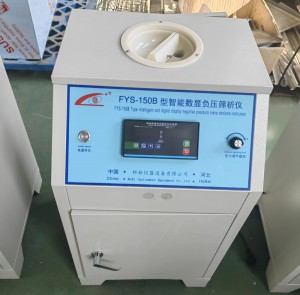

Concrete Cube Compression Testing Machine

Concrete Cube Compression Testing Machine

1,Installation and Adjustment

1. Inspection before installation

Before installation, check whether the components and accessories are complete and undamaged.

2. Installation program

1) Lift the testing machine in a suitable position in the laboratory and ensure that the casing is securely grounded.

2) Refueling: YB-N68 is used in the south, and YB-N46 anti wear hydraulic oil is used in the north, with a capacity of about 10kg. Add it to the required position in the oil tank, and let it stand still for more than 3 hours before the air has sufficient time to exhaust.

3) Connect the power supply, press the oil pump start button, and then open the oil delivery valve to see if the workbench is rising. If it rises, it indicates that the oil pump has supplied oil.

3. Adjusting the level of the testing machine

1) Start the oil pump motor, open the oil delivery valve, raise the lower pressure plate by more than 10mm, close the oil return valve and motor, place the level gauge on the lower pressure plate table, adjust the level to within ± grid in both the vertical and horizontal directions of the machine base, and use an oil resistant rubber plate to pad it when water is uneven. Only after leveling can it be used.

2) Test run

Start the oil pump motor to raise the workbench by 5-10 millimeters. Find a test piece that can withstand more than 1.5 times the maximum test force and place it in an appropriate position on the lower pressure plate table. Then adjust the hand wheel to make the upper pressure plate separate

Test piece 2-3mm, slowly pressurize by opening the oil supply valve. Then, apply a force value of 60% of the maximum test force for about 2 minutes to lubricate and exhaust the oil cylinder piston.

2、 Operation method

1. Connect the power supply, start the oil pump motor, close the return valve, open the oil supply valve to raise the workbench by more than 5mm, and close the oil supply valve.

2. Place the specimen in the appropriate position on the lower platen table, adjust the hand wheel so that the upper platen is 2-3 millimeters away from the specimen.

3. Adjust the pressure value to zero.

4. Open the oil delivery valve and load the test piece at the required speed.

5. After the test piece ruptures, open the oil return valve to lower the lower pressure plate. Once the test piece can be removed, close the oil supply valve and record the pressure resistance value of the test piece.

3、 Maintenance and upkeep

1. Maintaining the level of the testing machine

For certain reasons, the level of the testing machine may be damaged, so it should be regularly checked for level. If the level exceeds the specified range, it should be readjusted.

2. The testing machine should be regularly wiped clean, and a small amount of anti rust oil should be applied to the unpainted surface after wiping it clean.

3. The piston of the testing machine shall not rise beyond the specified position

Main purpose and scope of application

The 2000KN COMPRESSION TESTING MACHINE (hereinafter referred to as the testing machine) is mainly used for pressure testing of metal and non-metal specimens, such as concrete, cement, bricks, and stones.

Suitable for construction units such as buildings, building materials, highways, bridges, mines, etc.

4、 Working conditions

1. Within the range of 10-30 ℃ at room temperature

2. Install horizontally on a stable foundation

3. In an environment free of vibration, corrosive media, and dust

4. Power supply voltage 380V

|

Maximum test force: |

2000kN |

Testing machine level: |

1level |

|

Relative error of test force indication: |

±1%within |

Host structure: |

Four column frame type |

|

Piston stroke: |

0-50mm |

Compressed space: |

360mm |

|

Upper pressing plate size: |

240×240mm |

Lower pressing plate size: |

240×240mm |

|

Overall dimensions: |

900×400×1250mm |

Overall power: |

1.0kW(Oil pump motor0.75kW) |

|

Overall weight: |

650kg |

Voltage |

380V/50HZ |