Professional Servo Control Universal Testing Materials Tester

- Product Description

Computer Automatic Hydraulic Universal Testing Machine

1.Matters need attention

Please read this manual carefully before using this equipment, and keep it for future reference purposes

The installation environment requirements

① Environment temperature 10 ℃ ~35 ℃

② Relative humidity of not more than 80%

③ No vibration, no corrosion, no strong electromagnetic interference environment

④ The levelness should be no more than 0.2mm/1000mm

⑤ There should be around 0.7m space, equipment must be reliably grounding.

Power requirements

This equipment use 380v three-phase four-wire (in addition to the other tips) alternating current (AC), voltage stability, do not exceed ±10% of the rated voltage,the allowable current of the sockets shall not exceed 10A.

Hydraulic oil requirements

The equipment adopts standard hydraulic oil as the working fluid: when the room temperature is higher than 25 ℃ ,using No.68 anti-wear hydraulic oil . when the room temperature is below 25 ℃ ,using No.46 anti-wear hydraulic oil.

In winter, when the room temperature is too low, after turning on the machine please preheating equipment (start the oil pump motor) for 10 minutes. When frequent using, hydraulic oil should be replaced half a year, whether the fuel tank and filter should be cleaning or not is decided by the pollution degree .

This equipment can not use engine oil, gasoline or other oil for instead. Failure of the hydraulic component due to the improper Oil , will not be included in the scope of warranty.

About the emergency stop

In case of an emergency in the installation, operation, such as solenoid valves can not release, abnormal operation of motor, which may causes damage to the machine or injury of tester, please turn off the circuit breaker.

Precision

Equipment is exactly calibrated before leaving the factory, do not adjust the calibration parameters. Measurement error increases due to unauthorized adjustment for the calibration parameters, will not be included in the scope of warranty. You can contact with local quality supervision department for calibration according to the equipment marking accuracy class.

Maximum force

Determine the measuring range of equipment according to the equipment label, measuring range is adjusted in factory, do not alter the range parameter, adjustment of the range parameters could result in equipment output force is so large that causes damage to the mechanical parts or output force is so small that can not reach the setting value, the damage of mechanical components due to unauthorized adjustment for range parameters , will not be included in the scope of warranty.

2.General introduction

WAW series electro-hydraulic servo universal testing machine

WAW series electro-hydraulic servo universal testing machine is based on GB/T16826-2008 “electro-hydraulic servo universal testing machine,” JJG1063- 2010″electro-hydraulic servo universal testing machine,” GB/T228.1-2010 “metallic materials – method of tensile testing at room temperature”. It is a new generation material testing machine which developed and manufactured based on that. This series of testing machine is loaded with hydraulic , using the electro-hydraulic servo control technology for tensile testing, compress testing, bend testing,shear testing of metal and non-metallic materials,display a variety of curves,including stress, deformation, displacement and other closed loop control mode, can be arbitrarily switched in the experiment. It records and stores data automatically. It meets the GB,

ISO, ASTM, DIN, JIS and other standards.

The features of WAW series electro-hydraulic servo universal testing machine (type B):

① The test adopts microcomputer automatic control mode, with the functions of stress rate, strain rate, stress maintenance and strain maintenance;

② Adopt high-precision hub-and-spoke sensor to measure force;

③ Host which adopts four-column and double screws test spatial structure

④ Communicate with PC by high-speed Ethernet communication interface;

⑤ Manage test data by standard database;

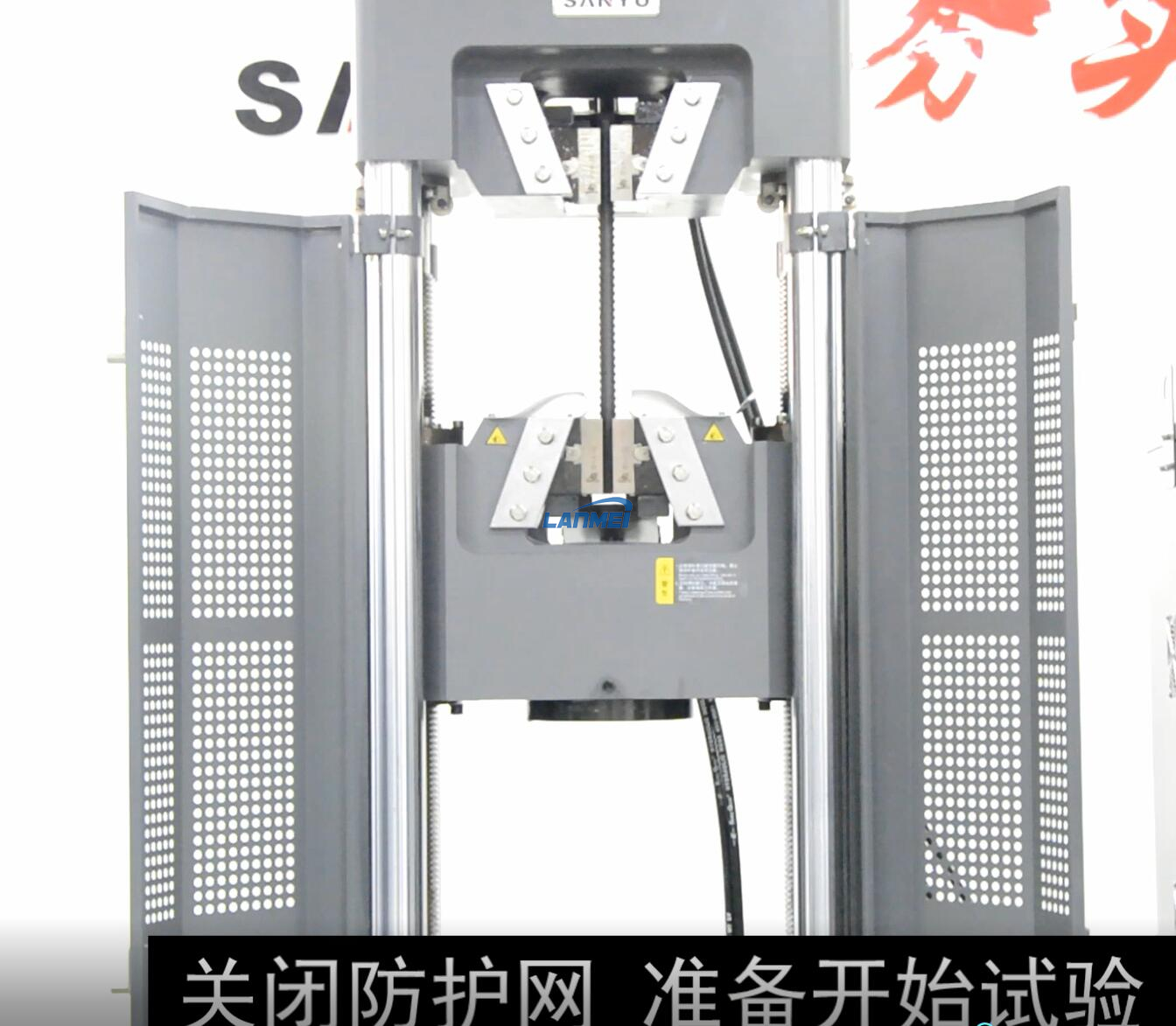

⑥ High strength, high toughness and beautiful protective net for safety protection

4.Installation and commissioning

Prepare installation tools

Check the accessories attached to the equipment according to the packing list, and check whether the accessories are complete Prepare screwdriver, adjustable spanner and a set of inner six angle wrench

Fix the main engine

Fix the equipment according to the fixed parameters of the foundation with reference to the foundation drawing (see the parameters and instructions of the foundation drawing in the appendix of this manual for details) Unscrew the hose joint of the oil plug please safekeeping, in order to avoid the loss and caused the inconvenience of moving machine in the future. The connection must be closely, and pad into the sealing washer.

The oil circuit connection

Fill the right amount of hydraulic oil according to the mark on the oil tank (wait at least 3 hours before officially use after filling the hydraulic oil , to facilitate the bubble discharge in the hydraulic oil by itself), after filling the hydraulic oil connect the main engine and the control cabinet with hose in accordance with the sign (hydraulic jaw type requires jaw pipeline installation),when installing the pipeline,one gasket must be put between pipeline and splice , and fasten the joint by wrench, as shown The unscrewed oil plug of the hose please be safekeeping, in order to avoid the loss and caused the inconvenience of moving machine in the future. When moving the equipment please tear down the pipelines and seal them by oil plug closely.

Electrical connection

Take down the the whole set of data lines, in accordance with the data line corresponding with the interface on the control cabinet left . Please connect the power cord in strictly accordance with the attached label. The null wire (line 4) of the three-phase four-wire power line is strictly prohibited from wrong connection.

Open the computer package, install the computer (this step is only suitable for models which containing computer ); then install one end of the RS-232 communication line on controller, the other end install on the computer. Please do not replace the computer along with the equipment.(Tips:this step is not required for industrial computer type )

Open the printer package and install the printer according to the installation instructions attached to the printer (this step is only applicable to models containing external printer);After the printer is installed and connected to the computer, place it in a convenient location (the printer driver is saved on the local disk of the computer and needs to be installed by yourself) .

The first operation and commissioning

After electrical installation finished, switch on the power of the equipment, turn on the equipment.Use the control panel on the control cabinet or control box ,to rise the middle girder some distance (if the beam falls,you should immediately stop the operation and adjust the power phase sequence), then in accordance with the manual, operate the equipment with no-load, durning the rising of the worktable (can’t exceed the maximum stroke),please observe if there is abnormal phenomenon, if it dose, you should uninstall and stop to check,remedy the trouble; if not, unloading until piston down to normal position, commissioning ends.

Equipment diagram