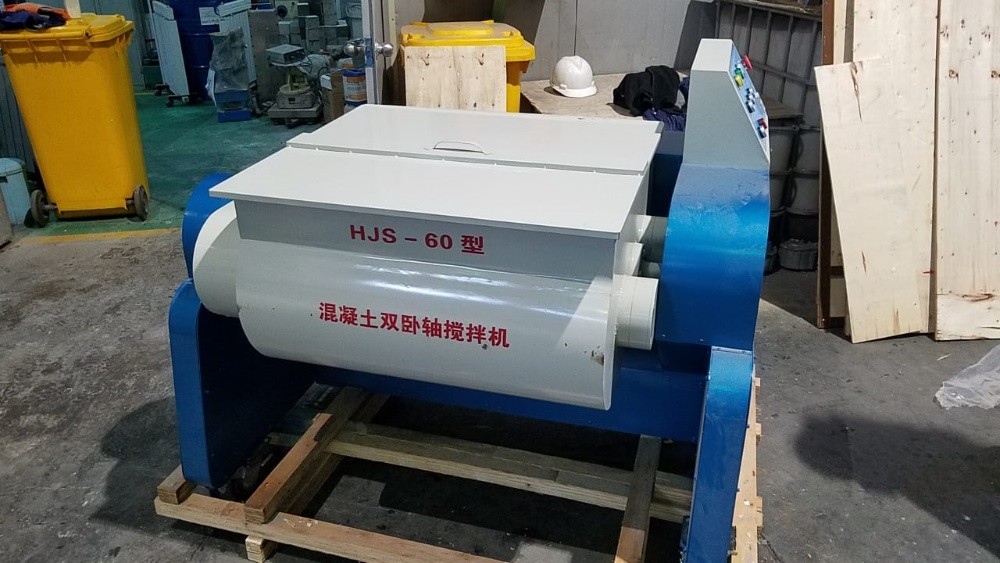

Forcing type double Horizontal Shaft laboratory Concrete Mixer, Blender, concrete mixing machine" is applicable to the construct science research unit and the construct company and the laboratories of concrete construction unit, can mix the common concrete and the light quality concrete, also can apply to the other profession laboratory to mix the different material. This machine construction is reasonable, the operation is convenient, high efficiency of mixing, even of mixing, the amount of remaining is little, the sealing is good, the powder is little, washing convenience, is the ideal equipments in the laboratory to use mix concrete.

This concrete mixer is used for laboratory usage, it's a forced type mixer with double horizontal shaft.

1.Connect the power plug to the power socket.

2.Switch on'air switch' , the phase sequence testing works. If the phase sequence errors ,' phase sequence error alarm' will alarm and lamp flashing. At this time should cut input power and adjust the two fire wires of the input the power.(note: cann't adjust the phase sequence in the equipment controller) if "phase sequence error alarm" don't alarm that phase sequence is correct, can be normal use.

3.Check whether the " emergency stop" button is open, please reset it if open (rotate according to the direction indicated by the arrow).

4.Put the Material to the mixing chamber, cover the upper cover.

5.Set mixing time (factory default is one minute).

6.Press the button 'mixing', mixing motor begins to work,reach to the setting time (factory default is one minute), machine stop working, finish mixing.If you want to stop in the process of mixing, can press the 'stop' button.

7.Take off the cover after mixing has stopped, place the material box at below center position of the the mixing chamber, and push the tight, lock the universal wheels of the material box.

8.Press the 'Unload' button,'unload' indicator light on at the same time.Mixing chamber turn 180 ° automatically stop, 'unload' indicator light is off at the same time, the most material is discharged.

9.Press the 'mixing' button,the mixing motor works, clear the residual material clean (need about 10 seconds).

10.Press the "stop " button, mixing motor stops working.

11.Press the 'reset'button,discharging motor running reversely, the 'reset' indicator light bright at the same time, the mixing chamber turn 180 ° and automatically stop, the 'reset' indicator light off at the same time.

12.Clean the chamber and blades to prepare mixing next time.

Note: (1)In the machine running process in case of emergency, please press the emergency stop button to ensure the personal safety and avoid the damage of equipment.

(2) When input the cement, sand and gravel,it is forbidden to mingle with the nails,iron wire and other metal hard objects, so as not to damage the machine.

Technical Specifications Structure: double horizontal shaft

Nominal capacity: 60L

Mixing motor power: 3.0kw

Unloading motor power: 0.75kw

Mixing drum material: 16mn steel

Mixing vane material: 16mn steel

Interval between vane and wall: 1mm

Drum wall thickness: 10mm

Vane thickness: 12mm

Overall size: 1100×900×1050

Net weight: approx 700kg

Operation and use

1. Connect the power plug to the power socket.

2. Switch on'air switch' , the phase sequence testing works. If the phase sequence errors ,' phase sequence error alarm' will alarm and lamp flashing. At this time should cut input power and adjust the two fire wires of the input the power.(note: cann't adjust the phase sequence in the equipment controller) if "phase sequence error alarm" don't alarm that phase sequence is correct, can be normal use.

3. Check whether the " emergency stop" button is open, please reset it if open (rotate according to the direction indicated by the arrow).

4. Put the Material to the mixing chamber, cover the upper cover.

5. Set mixing time (factory default is one minute).

6. Press the button 'mixing', mixing motor begins to work,reach to the setting time (factory default is one minute), machine stop working, finish mixing.If you want to stop in the process of mixing, can press the 'stop' button.

7. Take off the cover after mixing has stopped, place the material box at below center position of the the mixing chamber, and push the tight, lock the universal wheels of the material box.

8. Press the 'Unload' button,'unload' indicator light on at the same time.Mixing chamber turn 180 ° automatically stop, 'unload' indicator light is off at the same time, the most material is discharged.

9. Press the 'mixing' button,the mixing motor works, clear the residual material clean (need about 10 seconds).

10. Press the "stop " button, mixing motor stops working.

11. Press the 'reset'button,discharging motor running reversely, the 'reset' indicator light bright at the same time, the mixing chamber turn 180 ° and automatically stop, the 'reset' indicator light off at the same time.

12. Clean the chamber and blades to prepare mixing next time.

Note: (1)In the machine running process in case of emergency, please press the emergency stop button to ensure the personal safety and avoid the damage of equipment.

(2) When input the cement, sand and gravel,it is forbidden to mingle with the nails,iron wire and other metal hard objects, so as not to damage the machine.

Post time: May-06-2023