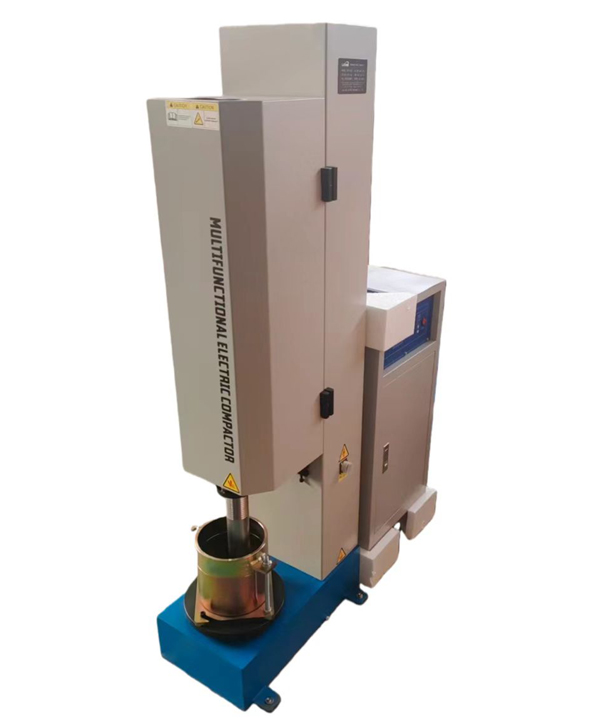

Lab Soil Compactor CBR Compaction Instrument

Lab Soil Compactor CBR Compaction Instrument

It is suitable for the foundation engineering construction such as water conservancy dam, traffic, railway, airport and building etc. With standard compaction method to determine the relationship between density and water ratio, then confirm the dry density and moisture content of soil.

It could satisfy the specimen preparation requirements of CBR tests and resilience modulus tests.

It could perform light compaction and heavy compaction. With perfect designation, it has lots of specialties such as digital display, auto number and auto circulation etc.

Proctor CBR (California Bearing Ratio) Soil Compactor is used for proctor compaction tests on soil samples, allowing for determining maximum dry density and optimum moisture content in geotechnical engineering according to standardized procedures. This process involves compacting soil samples in a standard mold under controlled conditions. This helps evaluate the mechanical strength of natural ground, subgrades, and base courses for pavement design, measuring the load-bearing capacity of soil when compacted to specific density and moisture content.

Product Overview:

This instrument can conduct compaction tests in accordance with ministerial and national standards. It is mainly used for compaction tests on cement – stabilized soil (before cement hydration) and lime – stabilized soil. The tests are driven by electricity, which reduces the labor intensity of scientific researchers and improves test efficiency. Based on the chain – drive system, it has been updated to use a rack – and – pinion drive, avoiding issues such as dropped hammers and hammers that cannot be lifted. It has features such as automatic counting, automatic control, automatic shutdown, automatic lifting of the hammer out of the test bucket after the test is completed, and automatic cyclic operation. It complies with the industry standard of the People’s Republic of China (JTG3430 – 2020) and is available for use in traffic scientific research departments, colleges and universities, engineering construction units, laboratories, and field tests. This enables accurate plotting of the curves between the water content and dry density (unit weight) of stabilized soil to determine the optimal water content and maximum dry density.

Soil Marshall Electric Hydraulic Demolding Machine

The compactor is suitable for the foundation engineering construction such as water conservancy dam, traffic, railway, airport and buildings etc.. With standard compaction method to determine the relationship between density and water ratio so as to confirm the dry density and moisture content of soil.

Automatic Soils Compactor

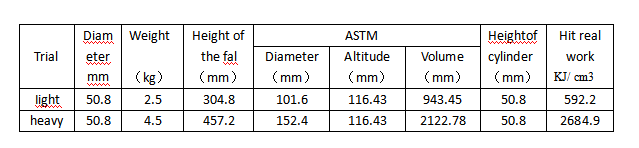

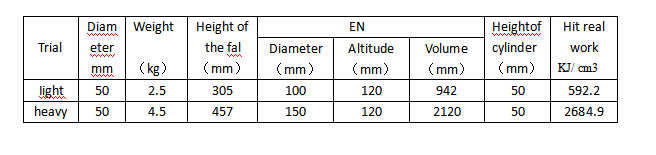

Complies to ASTM D558, ASTM D698, ASTM D1557, AASHTO T99, AASHTO T134, AASHTO T180 standards

The time and effort required to prepare specimens for compaction studies and other test methods can often be costly and time-consuming. The use of an automatic, mechanical compactor will show considerable cost benefits over hand compaction methods.

These machines automatically compact specimens eliminating the laborious hand compaction method. The height and weight of the rammer are adjustable to suit test requirements.

An automatic blow pattern ensures optimum compaction for each layer of soil in compliance with the standards. The rammer travels across the mould and the table rotates the mould in equal steps on a base that is extremely stable. The number of blows per layer can be set at the beginning of the test.

Preset blow pattern ensures an even compaction, includes solid state controls for reliability and maintenance. An automatic digital counter resets to zero on the completion of a test. The selectable rammer has a drop height of 300-450mm, a selectable rammer weight of 2.5 or 4-5kg. A preset number of blows per layer can be set by thumb wheel control. A compaction rate of approximately 26 blows per minute. Accepts BS Standard Compaction and CBR moulds; also meets the requirements of ASTM D558, ASTM D698, ASTM D1557, AASHTO T99, AASHTO T134, AASHTO T180.