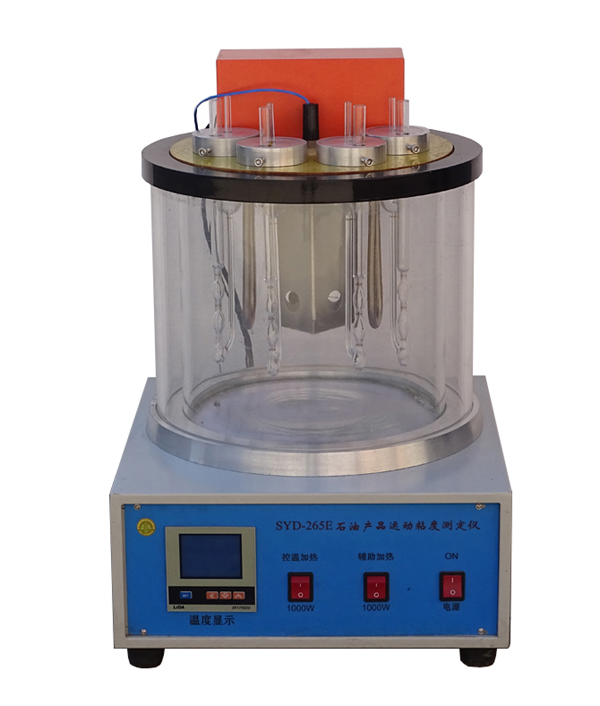

Petroleum product kinematic viscosity tester

Petroleum product kinematic viscosity tester

I. Purpose and Scope of Application

This method is applicable to the determination of the kinematic viscosity of viscous petroleum asphalt, liquid petroleum asphalt and their distillation residues by capillary viscometer.

2. Unless otherwise specified, the test temperatures are 135℃ (for viscous petroleum asphalt) and 60℃ (for liquid petroleum asphalt). To obtain the viscosity-temperature curve of viscous petroleum asphalt at high temperatures and determine the isoviscosity temperature as the construction temperature, it is advisable to use 120℃, 150℃ and 180℃ as the test temperatures.

3. In the industry standard JTG E20-2011 “Test Procedures for Asphalt and Asphalt Mixture in Highway Engineering”, T 0620-2000 “Kinematic Viscosity of Asphalt (Capillary Method)”

Ii. Main Technical Parameters

The temperature control range is from room temperature to 135℃

2. Temperature control accuracy: ±0.1℃

3. Heating power: Auxiliary heating, 1000W temperature control heating, 600W

4. Working voltage: 220V

5. Appearance dimensions: 420x450x630mm

6. Net weight of the instrument: 46kg

Petroleum Product Kinematic Viscosity Tester: An Essential Tool for Quality Control

The petroleum industry is highly dependent on the accurate measurement of various physical properties of its products, and kinematic viscosity is one of the most critical parameters. The kinematic viscosity of a petroleum product is an important indicator of its flow characteristics and performance under different temperature conditions. In order to accurately evaluate this characteristic, the kinematic viscosity tester of petroleum products plays a vital role.

The Petroleum Products Kinematic Viscometer is used to measure the viscosity of liquids, especially oils and fuels, under controlled temperature conditions. The instrument works by measuring the time required for a specific volume of liquid to flow through a calibrated capillary tube. The results are expressed in centistokes (cSt), giving you a clear understanding of the fluid’s properties.

The importance of kinematic viscosity testing cannot be overstated. It directly impacts the efficiency of engines, machinery, and various industrial processes. For example, a fuel with the wrong viscosity can lead to poor combustion, increased emissions, and possibly even engine damage. Similarly, a lubricant with the wrong viscosity may not adequately protect moving parts, causing wear.

Modern petroleum product kinematic viscosity testers are equipped with advanced features such as digital display, automatic temperature control, data recording, etc. These improvements not only improve the accuracy of the measurement, but also simplify the testing process and improve the efficiency of laboratories and quality control departments.

In summary, petroleum product kinematic viscometers are an indispensable tool for the petroleum industry. By ensuring that products meet the required viscosity standards, companies can improve performance, reduce operational risks, and remain compliant with industry regulations. As the demand for high-quality petroleum products continues to grow, kinematic viscometers will continue to play a key role in ensuring product integrity and reliability.