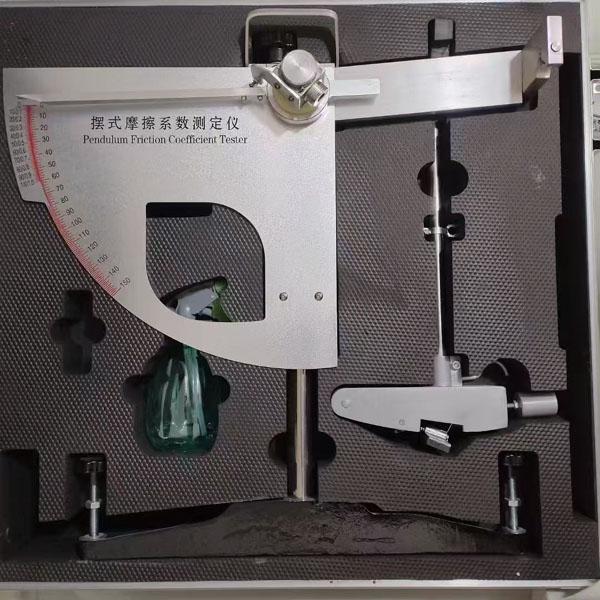

Lab Swing Frictionmeter Pendulum friction coefficient tester

Pendulum friction coefficient tester Lab Swing Frictionmeter

Accurate test results: This pendulum floor sliding resistance tester provides precise measurements, allowing users to confidently assess the sliding resistance of various floor surfaces. It is suitable for various environments, including laboratories and workplaces where safety is of paramount importance.

Easy to operate: The automatic tester can be operated with minimal user input, making it an ideal choice for those who need efficient testing without extensive training. Just set up the tester and let it do the work for you.

Durable structure: Constructed with high-quality materials, this electronic testing device is designed to withstand regular use and last for a long time. The wooden box provides additional protection during storage and transportation.

Portable and compact: Despite its powerful construction, this pendulum sliding resistance tester is designed to be compact and easy to move, making it perfect for use in various locations. Its dimensions of 700x340x740mm ensure that it can fit most storage spaces.

Comprehensive testing capabilities: This pendulum anti-slip tester is designed to meet the needs of a wide range of users, including those who need to test various floor types, such as ceramics, concrete, and wood.

Accurate measurement of surface friction performance: This manual pendulum sliding tester enables users to measure the anti-slip and friction properties of various surfaces with high precision, ensuring reliable results in the construction industry.

Compliant with international standards: The design of this product complies with BS 812:114 and EN 1097-8 standards, guaranteeing its quality and reliability in construction projects.

Durable structure: Made of high-quality steel, the tester can withstand regular use and last for a long time, minimizing maintenance and replacement costs.

Customization options available: Our OEM (Original Equipment Manufacturer) service allows for customized products to meet specific user needs, including branding and packaging.

One-year warranty, peace of mind: This product comes with a one-year warranty, providing users with assurance that they are protected against any defects or malfunctions during the warranty period.

The Pendulum Skid Tester measures the frictional resistance between a rubber slider mounted on the end of a pendulum arm and the test surface. This provides highway engineers with a routine method of checking the resistance of wet and dry surfaces to slipping and skidding, both in the lab and on site.

STANDARD

- BS EN 1097-8, 13036-4:2003

- AS/NZS 4586

- BS 6077 Pt1, 7044, 7188, 8204, 7976, 812 Pt. 144

- ASTM E303

Understanding the Lab Swing Frictionmeter: A Comprehensive Overview

The Pendulum Skid Tester measures the frictional resistance between a rubber slider mounted on the end of a pendulum arm and the test surface. This provides highway engineers with a routine method of checking the resistance of wet and dry surfaces to slipping and skidding, both in the lab and on site.

Applications

• Road surface testing

• Testing of new road surface materials under development

• Testing of aggregates in the PSV (polished stone value) test

• Testing of floors and pedestrian walkways

• Flooring materials product development

• Accident investigations, both traffi c and pedestrian

• Litigation investigations

Features

• Designed for laboratory and in situ road surface testing

• Dispatched calibrated to ASTM E-303

• Low friction arm, and lightweight pointer

• Comes with integral ‘F’ scale for use with small slider set for 76mm slide length. (PSV test)

• Repeatable and reproducible

• Supplied with robust carrying case

In the realm of material science and engineering, the measurement of friction is crucial for understanding the behavior of materials under various conditions. One of the most effective tools for this purpose is the Lab Swing Frictionmeter. This innovative device is designed to provide accurate and reliable measurements of friction coefficients, which are essential for a wide range of applications, from product design to quality control.

The Lab Swing Frictionmeter operates on a simple yet effective principle. It typically consists of a swinging arm that is attached to a sample material. As the arm swings, it creates a dynamic interaction between the sample and a reference surface. The frictional forces generated during this motion are measured, allowing researchers and engineers to calculate the friction coefficient of the material being tested. This coefficient is a dimensionless number that represents the ratio of the force of friction between two bodies and the force pressing them together.

One of the key advantages of the Lab Swing Frictionmeter is its versatility. It can be used to test a wide variety of materials, including metals, plastics, rubber, and composites. This makes it an invaluable tool in industries such as automotive, aerospace, and manufacturing, where understanding friction is critical for performance and safety. For instance, in the automotive industry, the friction properties of brake materials can significantly impact vehicle safety and efficiency. By using a Lab Swing Frictionmeter, engineers can ensure that they select materials that provide optimal performance under different conditions.

Another significant benefit of the Lab Swing Frictionmeter is its ability to simulate real-world conditions. Unlike static friction tests, which only measure the force required to initiate movement, the Lab Swing Frictionmeter provides insights into dynamic friction, which is often more relevant in practical applications. This dynamic testing capability allows for a more comprehensive understanding of how materials will behave in actual use, leading to better product design and improved performance.

Moreover, the Lab Swing Frictionmeter is designed with user-friendliness in mind. Many models come equipped with digital displays and data logging capabilities, making it easy for users to record and analyze their results. This feature is particularly beneficial for researchers and engineers who need to compile data for reports or presentations. Additionally, the compact design of many Lab Swing Frictionmeters allows for easy integration into laboratory settings without requiring extensive space or specialized equipment.

In terms of maintenance, the Lab Swing Frictionmeter is relatively low-maintenance, requiring only periodic calibration to ensure accuracy. This reliability makes it a cost-effective solution for laboratories and industries that require consistent and precise friction measurements.

In conclusion, the Lab Swing Frictionmeter is an essential tool for anyone involved in material testing and analysis. Its ability to measure dynamic friction coefficients accurately and its versatility across various materials make it invaluable in numerous industries. As technology continues to advance, the Lab Swing Frictionmeter will undoubtedly play a crucial role in the ongoing quest for improved material performance and safety. Whether you are a researcher, engineer, or quality control specialist, investing in a Lab Swing Frictionmeter can enhance your understanding of material behavior and contribute to the development of superior products.