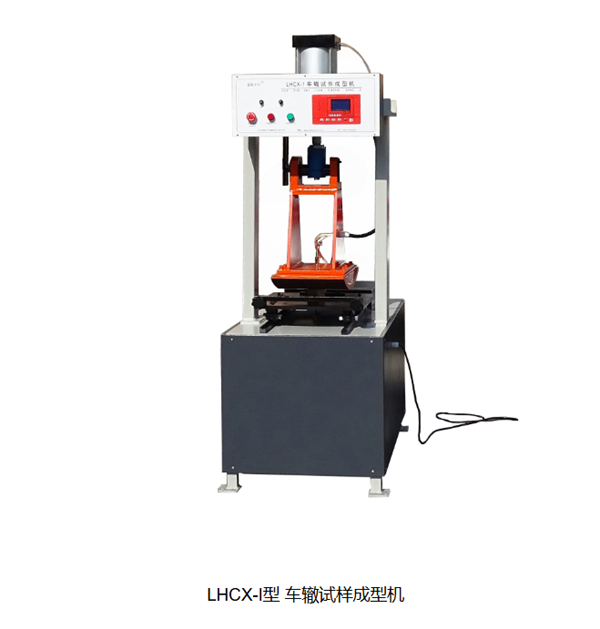

Lab Asphalt Rutting Sample Forming Machine

Asphalt Rutting Sample Forming Machine

I. Overview

The LHCX-I type rutting sample forming machine is the latest highway instrument laboratory equipment developed by our company recently. It integrates mechanics, electricity and pneumatics. Compared with similar products, it has the characteristics of small volume, high degree of automation, strong functions and convenient operation, and is at the leading level in China. This machine is mainly used for rolling and forming asphalt mixtures during rutting tests, and is also suitable for making samples by the roller method for other physical and mechanical property tests of asphalt mixtures. This machine and the test method fully comply with the requirements of the JTJ052-2000 (T0703-1993) standard.

Ii. Main Technical Indicators

Test mold specification: 300×300× (30-110mm)

The stroke of the test mold car is 300mm.

The height variation value of the test mold is 30 to 100mm.

4. The pressure of the roller is within the range of 0 to 20KN and can be adjusted freely.

The radius of the roller is 500mm and the width is 300mm.

6. Preheat the tiles at 20 to 200 degrees Celsius, which can be set arbitrarily (usually set at 100).

Asphalt rutting specimen forming machine: an essential tool for road surface testing

Asphalt rutting machines are key equipment in the field of civil engineering and pavement testing. Designed to simulate the effects of heavy traffic on asphalt pavement, the equipment plays a vital role in evaluating the durability and performance of asphalt mixtures.

Asphalt rutting is a common pavement problem where the pavement deforms under repeated traffic loads. This deformation can cause serious structural damage and safety hazards, so engineers must assess the rutting risk of asphalt mixes before using them in road construction. Asphalt rutting machines can create standardized test pieces and test them under controlled conditions, providing valuable data on material performance.

The asphalt rutting specimen forming machine is easy and efficient to operate. Usually, it heats the asphalt mixture to a specific temperature and then puts it into a mold. The machine then applies a predetermined load to the specimen to simulate the stress under actual working conditions. This process not only helps to shape the specimen, but also evaluates its anti-rutting performance.

In addition to the main functions, the asphalt rutting machine is equipped with advanced features that enhance its ease of use. Many models are equipped with a digital display to precisely control the temperature and applied load, ensuring that the results are accurate and repeatable. In addition, the machine’s rugged construction ensures its longevity and reliability, making it a worthwhile investment for laboratories and testing institutions.

All in all, the Asphalt Rutting Tester is an indispensable tool for engineers and researchers working to improve the performance of asphalt pavement. The device provides a reliable method for assessing rutting potential, making an important contribution to building safer, more durable roads.

It is mainly used for compacting slab asphalt mixture specimens, can compact specimens of various specifications, and the slab specimens used for Hamburg wheel tracking tests. Adopts cylinder loading and the servo motor controls the forward and backward of the test mould.

Features

l The roller pressure is controlled by the pneumatic system and can be adjusted arbitrarily within the range of 0~30KN.

l The servo motor is used to control the forward and backward of the test mould, and the maximum speed can reach 300mm/s.

l The height of the test mould can be adjusted arbitrarily within the range of 30mm~150mm.

l Large wheel temperature control range, high precision, and good stability. Adopts PWM modulation method for temperature PID control, which can be set arbitrarily according to the test requirements.

l Touch screen control and display, working parameters can be saved, easy to operate and easy to set.

l The data of the test process can be displayed in curves, including temperature, pressure, and height of the specimen, and the data can be exported by U disk.

l The equipment has the self-diagnosis function and the fault code prompt.

l The clamping mechanism for installing the test mould is easy to use, safe and reliable.

l Two stop modes, stop by number of times and stop by height (only models with height test module).

l The number of rolling times of the specimen can be set arbitrarily and displayed in real time. When the actual number of rolling times reaches the set value, the rolling will stop automatically.

l The height of the specimen can be displayed in real time with an accuracy of 0.1mm (optional).

l Roller has vibration pump (optional).