ISO Standard Concrete Testing Rebound Hammer Calibration Tester

ISO Standard Concrete Testing Rebound Hammer Calibration Tester

Precise Calibration: This G216 anvil is designed for the precise calibration of concrete testing hammers, ensuring accurate measurements in accordance with ISO standards.

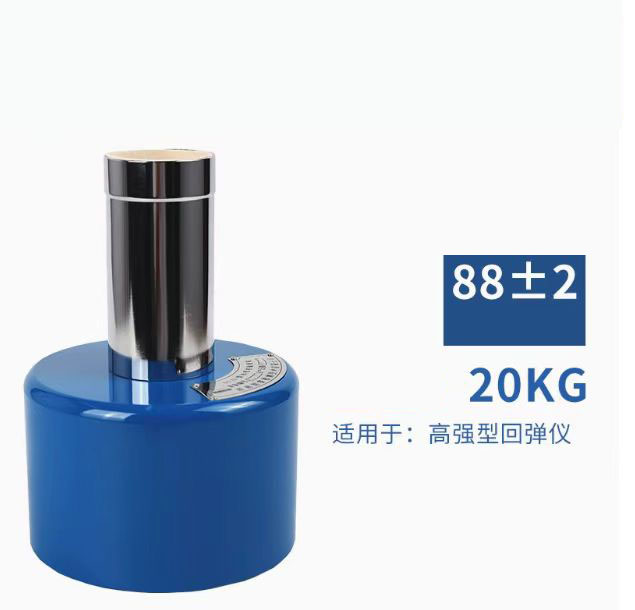

Durable Structure: Weighing 16kg, 20kg ,this heavy anvil is built to withstand repeated use and provides reliable performance in demanding testing environments.

Easy to Use: The hydraulic power of the anvil makes for effortless operation, allowing users to focus on precise calibration without worrying about their own performance.

Compliant with International Standards: The G216 anvil complies with ISO standards, making it suitable for various industries and applications, including construction and quality control.

Suitable for [Your Application]: Whether you are a quality control expert or an architectural engineer, this calibration anvil is highly suitable for [Your specific use case or industry], providing accurate and reliable results.

ModelG216: weight 16kg

Model G218:weight 20kg Suitable for high-strength rebound testers

Concrete Testing: Importance of Rebound Hammer Calibration Tester

Concrete is one of the most widely used building materials in the world, renowned for its strength, durability and versatility. However, rigorous testing is essential to ensure that concrete structures meet safety and performance standards. One of the most effective ways to assess concrete quality is with a rebound hammer, a tool that measures the surface hardness of concrete. To ensure accurate results, it is vital that the rebound hammer is properly calibrated, which is why concrete testing rebound hammer calibrators have become an indispensable tool in the construction and civil engineering fields.

Understanding Rebound Hammer

A rebound test hammer, also known as a Schmidt hammer, works on a simple principle: it measures the force that rebounds after a spring-loaded object strikes a concrete surface. The hardness of the concrete affects how far the object rebounds, which in turn correlates to the concrete’s compressive strength. This nondestructive testing method is popular because it is quick and easy to use, allowing engineers and construction professionals to quickly assess the quality of concrete without causing damage.

Necessity of calibration

Although reliable, rebound hammers can suffer in accuracy if they are not properly calibrated. Calibration is the process of adjusting the rebound hammer to ensure it provides accurate measurements. Factors such as wear, environmental conditions, and changes in the composition of concrete can affect the performance of the rebound hammer. Therefore, regular calibration is essential to maintain the integrity of the testing process.

The Concrete Testing Hammer Calibration Tester is designed to simplify the calibration process. It provides a controlled environment where the hammer can be tested against a known standard. By using the calibration tester, the operator can ensure that the hammer is working properly and providing reliable data.

Calibration Process

The calibration process usually consists of several steps. First, the rebound hammer is tested against a reference standard (a concrete block of known hardness). The rebound value measured by the rebound hammer is compared to the expected value of the reference standard. If a difference is found, the rebound hammer can be adjusted to ensure the reading is accurate.

In addition to checking the accuracy of the rebound hammer, calibrating the tester can also help identify any potential problems with the tool itself. For example, if the rebound hammer consistently reads too low or too high, it could indicate a damaged internal mechanism or worn springs. Regular calibration can help detect these problems early, avoiding costly mistakes in concrete assessment. Benefits of Using a Calibration Tester

There are many benefits to using a concrete test hammer to calibrate your tester. Firstly, it improves the accuracy of concrete testing, ensuring engineers can make informed decisions based on reliable data. This is especially important in critical applications such as bridges, high-rise buildings and other safety-critical structures.

Additionally, regular calibration can extend the life of a rebound hammer. By identifying and resolving issues early, operators can avoid costly repairs or replacements. Additionally, maintaining accurate testing equipment can improve the overall efficiency of a construction project, reducing delays caused by retesting or structural failures.

in conclusion

In summary, concrete test hammer calibrators play a vital role in ensuring accuracy and reliability in concrete assessments. As the construction industry continues to evolve, the importance of accurate testing methods cannot be overstated. By investing in proper calibration practices, construction professionals can improve the safety and durability of concrete structures, ultimately helping to maintain the integrity of the built environment. Regular use of calibrators not only ensures accuracy of measurements, but also promotes a culture of quality and safety in the construction industry.