High Quality Automatic Asphalt Softening Point Tester Lab

High Quality Automatic Asphalt Softening Point Tester

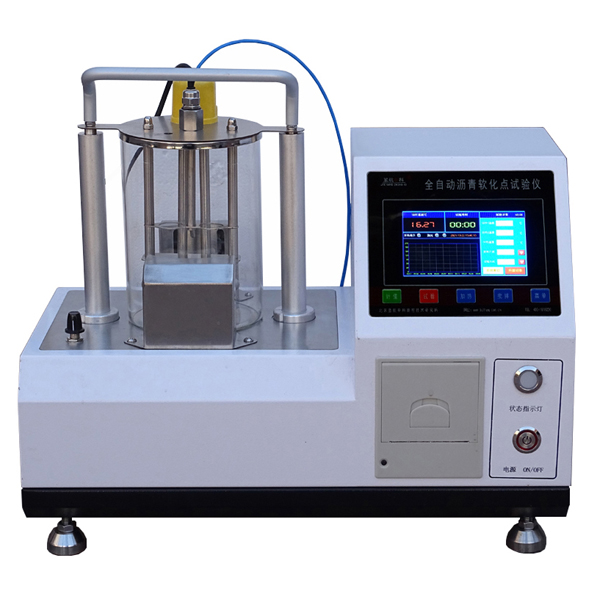

The SYD-2806G automatic asphalt softening point tester is designed and manufactured in accordance with the requirements stipulated in the People’s Republic of China standard GB/T 4507 “Method for Determining the Softening Point of Bitumen (Ring and Ball Method)” and the People’s Republic of China industry standard JTG E20-2011 “Test Procedures for Bitumen and Bituminous Mixtures for Highway Engineering” T 0606-2011 “Test for Softening Point of Bitumen (Ring and Ball Method)”. It is suitable for determining the softening point of road petroleum asphalt and polymer modified asphalt, and is also applicable to the determination of liquid petroleum asphalt, coal tar pitch distillation residue or emulsified asphalt evaporation residue. It can also be used to determine the softening point of some resin materials.

I. Main Technical Features

The water bath experiment can be conducted at 5 to 90℃, or the glycerol experiment can be carried out at 35 to +160℃.

2. It adopts microcomputer control, automatic stirring, and linear heating, maintaining a standard heating rate of 5℃/min.

3. The laser beam sensor is used to automatically detect the asphalt softening point value when the asphalt softens by 25.4mm. After the experiment is completed, the test results are automatically displayed and printed.

4. The heating rate is automatically recorded and can be queried through the query function for the temperature increase record of each minute.

5. It adopts a 7-inch LCD touch screen and a dual-language operating system in both Chinese and English.

6. The beaker is made of high-temperature resistant glass, and the specifications and dimensions of the steel ball positioning ring, steel balls, etc. meet the standard requirements.

7. The compact desktop structure features a separated control system and heating system (one on the left and the other on the right), which prevents electronic components from malfunctioning due to the high temperature during heating system tests.

II. Main Technical Parameters and Indicators

1.Input power supply: AC (220 ± 10%) V, 50 Hz

2. Temperature resolution: 0.1℃

3. Measuring range: When the softening point of the sample is ≤ 80℃: 20℃ to 90℃, use distilled water as the heating medium.

When the softening point of the sample is greater than 80℃: 70℃ to 160℃, glycerol is used as the heating medium.

4. Heating rate: Automatically adjusted to (5 ± 0.5) °C/min three minutes after the test starts.

5. Heating power: 650W

6. Medium stirring: Magnetic stirring, with a stirring speed of (0 – 300) revolutions per minute, inorganic variable speed.

7. Effective volume of the beaker: 1000 ml

8. Data shows: Touch LCD display

9. Communication interface: RS-232C

10.Applicable environment: 15℃ to 35℃

11.Relative humidity: ≤ 85%

12. Overall power consumption: < 700W

13. Dimensions: 420mm × 270mm × 370mm (length × width × height)

14.Overall weight: 12 kg

The sample is cast in shouldered rings and heated at a controlled rate under the weight of a steel ball. The softening point is the temperature at which the bitumen disks soften and sag downward at a specified distance.

The Tanaka asp-6 automates the softening point test by ring-and-ball mehod for bitumen and similar substances.Ergonomic, versatile and premium, the photo-electric device with a wide light beam is employed to ensure a reliable automatic detection of softening point. The automated asp-6 reliably tests the softening point of bitumen and other materials. Its compact size allows it to be installed in a fume hood, and includes a built-in safety shutdown in the event of harmful vapor generation from overheated glycerin. The softening point tester has an ergonomically color-coordinated display for high-visibility and intuitive switch operation. The all-in-one chassis design is compact, lightweight and premium.

1. This instrument adopts 32-bit ARM processor, color touch LCD screen, laser detection and other advanced technologies. It has the characteristics of homogeneous medium temperature, stable medium heating rate, automatic detection of softening point, excellent repeatability and reproducibility of test results.

2. The detection algorithm is advanced, and the influence of air bubbles generated in the heating process of filter media on the test results can be achieved.

3. It can do two samples at the same time.