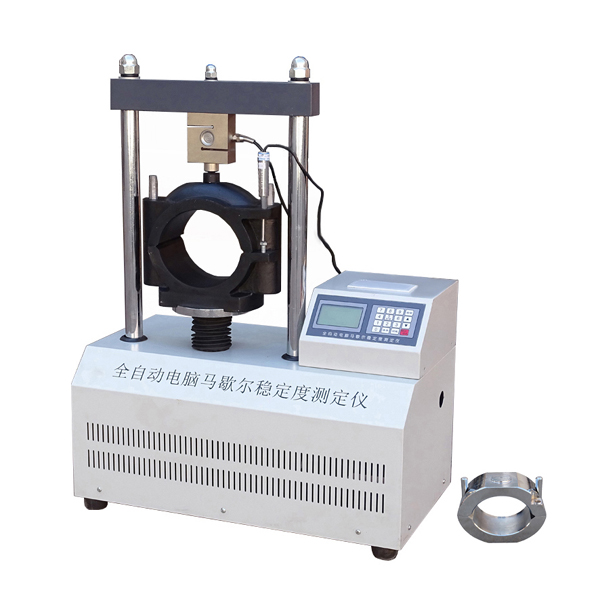

Computer Marshall Stability Tester For Lab

Computer Lab Marshall Stability Tester

This instrument is designed and manufactured in accordance with the requirements stipulated in the industry standard JTG E20-2011 “Test Procedures for Asphalt and Asphalt Mixture in Highway Engineering” of the People’s Republic of China, specifically T0709-2011 “Marshall Stability Test for Asphalt Mixture”. It is suitable for the Marshall stability test of asphalt mixture and can accurately determine the failure point of asphalt mixture, which is used for the mix proportion design of asphalt mixture or the quality inspection of asphalt pavement construction.

I. Main Technical Features

1. This instrument is equipped with functions such as parameter setting, measurement calibration, automatic test control, automatic data collection, and real-time clock. The control device simultaneously collects test data on the stability and flow value of the specimen and automatically determines the peak value.

2. The instrument features a large-screen graphic LCD display that directly shows the test data and curve graphs of stability and flow values, test results, and test time in Chinese characters, providing an intuitive display effect.

3. The instrument can store up to 100 sets of test data and test times internally, which can be retrieved and viewed at any time. The entire test is automatically completed and can automatically return to the initial position.

4. The instrument also has manual control functions for ascending, descending, and stopping, facilitating user operation.

Note: 1. The Ф100mm specimen loading fixture is the standard configuration of this instrument.

2. Specimen loading fixtures: 1 set each of Ф100mm and Ф150mm.

II. Main Technical Parameters and Indicators

1. Maximum load: 50kN.

2. Measuring range: ≤40kN.

3. Measuring error: ≤±0.1kN.

4. Overload protection function: Automatic protection when load value exceeds 49kN.

5. Vertical deformation (flow value): Measuring range 0~20mm. Measuring error ≤±0.05mm.

6. Press ascending speed: (50±5)mm/min.

7. Communication interface: RS232 serial communication port for communication with computer.

8. Working voltage: AC220V±10%, 50Hz.

9. Ambient temperature: 0℃~60℃.

10. Dimensions: 600mm×380mm×840mm (length×width×height).

11. Motor power: 550W.

12. Weight (net weight): 98kg. Computer Marshall Stability Tester

Marshall Laboratory Stability Tester: A Comprehensive Overview

The Marshall Stability Tester is an essential laboratory equipment in the field of civil engineering, especially for the analysis and design of asphalt mixtures. This test equipment is designed to evaluate the stability and flow characteristics of asphalt samples, providing key data for pavement quality and performance.

The core principle of the Marshall Stability Tester is based on the Marshall Method developed in the 1930s. This method evaluates the load-bearing capacity of asphalt mixtures by measuring the maximum load a specimen can withstand before failure and the deformation that occurs under that load. The test results of the Marshall Stability Tester are crucial to determine the optimal asphalt binder content and ensure that the mixture meets durability and performance requirements.

In a laboratory setting, the Marshall Stability Tester is typically used in conjunction with other equipment, such as an oven for heating the asphalt sample and a mold for shaping it. The test process involves preparing a cylindrical asphalt sample and then subjecting it to a controlled loading process. The tester measures peak load and flow values, providing insight into the mix’s stability and resistance to deformation under traffic loads.

The importance of the Marshall Stability Tester in laboratory applications cannot be overstated. Not only does it help engineers design better asphalt mixtures, it also plays a vital role in quality control during the asphalt pavement production process. By ensuring that materials used in road construction meet strict performance standards, the Marshall Stability Tester helps improve the life and safety of roads.

In summary, the Marshall Stability Tester for laboratory applications is a fundamental tool in the field of asphalt testing. It provides reliable data on the stability and flow properties of asphalt mixtures and is an essential tool for engineers and researchers working to improve road infrastructure.