Automatic Vicat Apparatus Cement

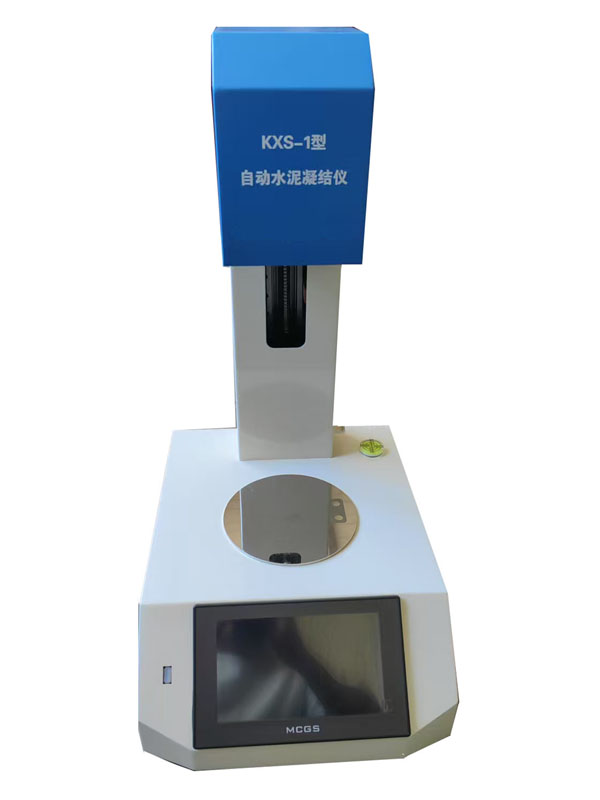

Cement Automatic Vicat Apparatus

Vicat apparatus, also called cement consistency setting time tester. It is a testing instrument for cement and concrete industries. It is mainly used to test the standard consistency water requirement and setting time of cement paste.

This instrument is mainly suitable for Portland cement, ordinary Portland cement, slag Portland cement, fly ash Portland cement, pozzolanic Portland cement, composite Portland cement and other varieties designated cement.

The cement standard consistency net slurry has a certain resistance to the sinking of the standard test rod. By testing the penetration of cement paste with different water content, the amount of water needed to be added to the cement standard consistency paste is determined.

The instrument is mainly composed of chassis bracket, touch display, screw lifting system, sliding component, and displacement measurement system.

- Technical Specification

|

Number |

Parameters |

Technical indicators |

|

1 |

Time control |

Display resolution: 0.1s control precision: ≤±0.1s |

|

2 |

Displacement |

Adapt high precision LVDT displacement sensor, split structure, without friction when needle dropping range 0~50mm, display precision: 0.01s Relative displacement accuracy: ≤±0.1mm |

|

3 |

Storage data |

200 groups |

|

4 |

Sliding component |

300g±1g(include needle and rod) |

|

5 |

Data interface |

RS485 |

|

6 |

Dimension |

390x310x575mm |

|

7 |

Voltage |

220±10%VAC/50HZ |

|

8 |

Power |

40w |

|

9 |

Net weight |

12kg |

- Feature

- [One-key operation of position calibration] Automatic Vicat Apparatus Cement Fully automatic calibration, the machine will automatic calibrate the precision position after rough position calibration

- [Position memory storage] After completed calibration of each test position, the meter will automatic store data, no need to repeat calibration;

- [Automation of the measurement process] One-key operation, automatic measurement, and automatic lifting of the components after the measurement is completed;

- [Precise time control] 30 seconds of settlement time countdown precise control;

[Judgment of test results] Judge the result data according to the requirements of

- the test specification, and prompt the operation;

- [Data storage] Standard consistency and setting time data are stored organically and uniformly, and can transfer and export;

- Data interface] Support RS485 interface data output, import computer standard format test report software;

- Operation steps

- Prepare before test

- Please read the instruction manual carefully before using the instrument. More help can be found in the “Help Document” on the touch screen.

- According to the requirements specified in the standard, prepare various test instruments and materials for testing;

- Check the working environment status of the instrument to make it meet the working environment and working conditions specified in the manual;Automatic Cement Vicat Apparatus