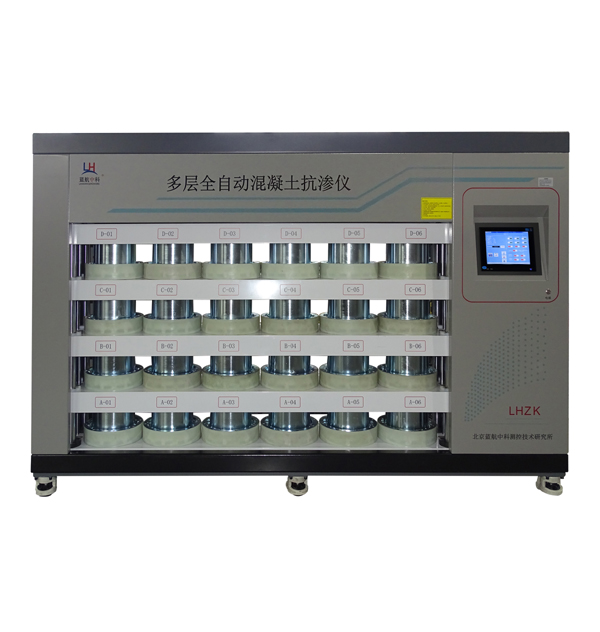

Automatic Sealing Concrete Impermeability Tester

Automatic Sealing Concrete Impermeability Tester

I. Product Introduction

This instrument Automatic Sealing Concrete Impermeability Tester adopts pure imported chips, Win7 operating system, and is centered on a computer with an integrated circuit high-precision control system. The software and hardware adopt multiple anti-interference measures, and the on-site working parameters are stored in real time. It features high control accuracy, no data loss upon power failure, and high reliability. It realizes the characteristics of systematization, intelligence, automation, and humanization of the equipment, and comprehensively leads similar products in the market. It complies with the requirements of standards such as GB/T50081-2008 (Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete), JG/T249-2009, T0528-94, and GBJ81-85.

II. Product Features

Six groups of specimens work simultaneously each time (the levels are based on the host machine), completely independently of each other. There are six independent water pumps corresponding to each level.

2. The machine body adopts a bookshelf rear-mounted design with a linked rotating transmission. There are no columns on both sides of the mold for testing, providing a large space between specimens and making it more convenient to install and remove specimens. It is suitable for customers in both large and small laboratory environments.

3. The mold testing adopts the latest seamless steel pipe welding technology. The appearance has undergone heat treatment and galvanization, which is not only aesthetically pleasing but also highly corrosion-resistant. It will not cause damage to the machine itself due to moisture, making it safer and more durable.

4. The airbags are made of imported high-quality Neoprene rubber through die-casting. Neoprene rubber contains over 95% pure natural rubber. The rubber thickness reaches 6 millimeters, providing better pressure resistance and wear resistance. The air pressure is generated by a precise high-pressure pump, which is greater than the water pressure, making it safer and more reliable.

5. Safety in use: The pneumatic connecting rod is mechanically locked. In case of power failure during mold testing, it will automatically stop at the current position and will not drop, ensuring a safe and reliable protection function.

6. By using individual sealed rubber sleeves for separate gas and water supply, 36 test blocks can be made on 6 layers, which improves efficiency, reduces costs and saves space.

7. The GD120F type Fuma universal industrial load wheels are adopted, which are durable, smooth and convenient for movement.

III. Product Technical Parameters

1.Control and working mode: The entire process is fully automatic testing, no need to apply any sealing materials. It features automatic sealing, automatic pressurization, automatic constant pressure, automatic leakage detection, automatic monitoring, and recording of time for reports, etc. It meets the requirements for network connection in the later stage.

2. Operating mode: Industrial computer with Windows 7 operating system, operated by a Chinese touch screen (with built-in measurement and control software)

3.Number of specimens that can be tested at one time: 36

4. The geometrical dimensions of the test mold (also known as the main mold): upper opening diameter φ175mm, lower opening diameter φ185mm, height 150mm.

5.Measurement range: 0 – 2 MPa

6. Relative error of the testing machine indication: ±1%

7.Repeatability relative error of the testing machine indication: 1%

8. Return-to-zero relative error: 0.5%

9.Minimum display accuracy of water pressure: 0.001 MPa

10. Equipment voltage stabilization start difference (permeation height method): ±0.025 MPa

11. Equipment voltage stabilization start-up difference (step-by-step pressurization method): ±0.005 MPa

12.The height of the topmost sample placement: 1.65 meters

13.The height of the bottom layer sample placement: 0.30 meters

14. Dimensions: 2641 * 811 * 2258 mm

15. Area: approximately 2.14 square meters

16. Net weight: 1.9 tons

17. Installation conditions: Can fit through a regular door, plug-and-pull connection, household power supply.

IV. Operating Instructions:

Select the layer you need to operate on, click the letter of that layer, enter the password [1], click [Confirm], and then you will enter the operation page.

2. Unlock the [Safety Lock], click [Rise], and after it stops, place the test piece inside.

3. Click [Exhaust], then click [Vacuum] to perform the vacuuming operation. After 3 to 4 seconds, turn off [Exhaust], and then turn off [Vacuum].

4. Click [Descend], wait until it stops, then turn off the [Safety Lock].

5. Click “Start”, the device begins to work and the test starts.

6. Click [Back] to return to the main page.

7. When three specimens are found to be leaking in the layer being operated on, it indicates that the color of the specimens is red, the test is completed, and the test for this layer will automatically stop.

8. Select the completed floor of the test and enter by inputting the password.

9. Repeat [Step 3]

10. Unlock the [Safety Lock], then click [Rise]. After it stops, remove the test piece.Automatic Sealing Concrete Impermeability Tester

Asphalt testing equipment products: