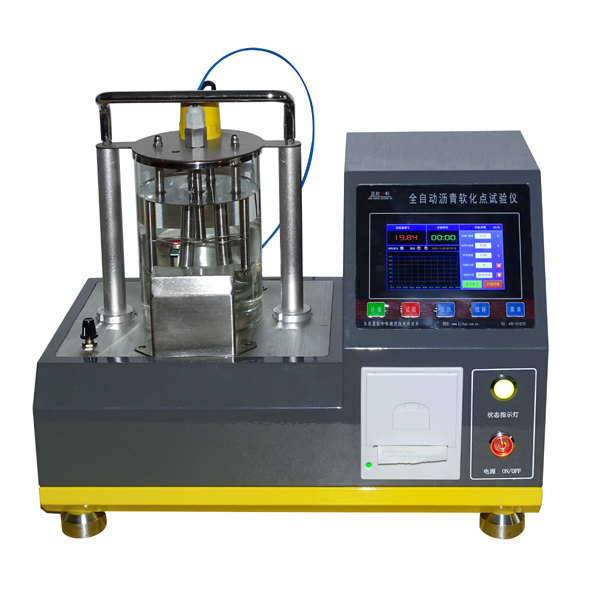

Automatic Asphalt Softening Point Tester

Automatic Asphalt Softening Point Tester

The automatic asphalt softening point tester is designed and manufactured in accordance with the requirements stipulated in the People’s Republic of China standard GB/T 4507 “Method for Determining the Softening Point of Bitumen (Ring and Ball Method)” and the People’s Republic of China industry standard JTG E20-2011 “Test Procedures for Bitumen and Bituminous Mixture in Highway Engineering” T 0606-2011 “Test for Softening Point of Bitumen (Ring and Ball Method)”. It is suitable for determining the softening point of road petroleum asphalt and polymer modified asphalt, and is also applicable to the determination of liquid petroleum asphalt, coal tar pitch distillation residue or emulsified asphalt evaporation residue. It can also be used to determine the softening point of some resin materials.

I. Main Technical Features

1.The water bath experiment can be conducted at 5 to 90℃, or the glycerol experiment can be carried out at 35 to +160℃.

2. It adopts microcomputer control, automatic stirring, and linear heating, maintaining a standard heating rate of 5℃/min.

3. The laser beam sensor is used to automatically detect the asphalt softening point value when the asphalt softens by 25.4mm. After the experiment is completed, the test results are automatically displayed and printed.

4. The heating rate is automatically recorded and can be queried through the query function for the temperature increase record of each minute.

5. It adopts a 7-inch LCD touch screen and a dual-language operating system in both Chinese and English.

6. The beaker is made of high-temperature resistant glass, and the specifications and dimensions of the steel ball positioning ring, steel balls, etc. meet the standard requirements.

7. The compact desktop structure features a separated control system and heating system (one on the left and the other on the right), which prevents electronic components from malfunctioning due to the high temperature during heating system tests.

Automatic asphalt mixer: a revolution in road construction

In the ever-evolving construction industry, the need for efficiency and precision has driven the development of advanced machinery. Among these innovations, automated asphalt mixers stand out as game-changers in the asphalt production process. These advanced machines are designed to streamline the asphalt mixing process, ensuring a consistent, high-quality product that meets the stringent standards of modern road construction.

Automated asphalt mixers use cutting-edge technology to automate the mixing process, significantly reducing the time and manpower required compared to traditional methods. Equipped with advanced sensors and control systems, these mixers are able to accurately measure and mix various materials, including aggregates, asphalt and additives, to prepare the perfect asphalt mixture. This level of automation not only increases production efficiency, but also minimizes the risk of human error, resulting in a more reliable end product.

One of the key benefits of automated asphalt mixers is their ability to maintain precise temperature control during the mixing process. This is critical because the viscosity of asphalt greatly affects its properties. By ensuring the material is mixed at the optimal temperature, these mixers are able to produce durable asphalt that can withstand the stress of heavy traffic and varying weather conditions.

In addition, automated asphalt mixers integrate smart technology that enables real-time monitoring and data collection. Operators can remotely track the mixing process and make adjustments as needed to ensure the highest quality output. This feature is especially beneficial for large-scale projects where consistency is important.

All in all, fully automated asphalt mixers are revolutionizing the road construction landscape. By improving efficiency, precision, and quality, these machines are paving the way for safer, more durable roads, ultimately contributing to the advancement of infrastructure around the world. As the industry continues to embrace automation, the future of the asphalt mixing industry looks bright.