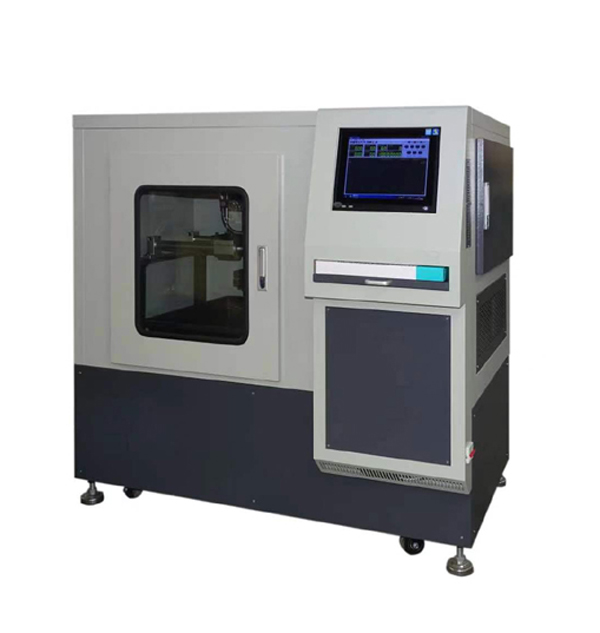

Automatic Asphalt Mixture Rutting Tester (Popularization)

Automatic Asphalt Mixture Rutting Tester (Popularization)

Main technical features:

Intelligent type: Automatically generate and save test results; conveniently call up historical data and output test reports.

2. Point-to-point data acquisition: The upper and lower microcomputer measurement and control system is adopted to ensure the repeatability of deformation quantity acquisition in space.

3. High data acquisition resolution and fast speed: It adopts an analog-to-digital converter with a resolution of 16 bits and an acquisition rate of 100 kHz.

4. Wide temperature control range, high precision and good stability: Temperature PID control is carried out by using PWM modulation.

5. Good electromagnetic compatibility and high reliability: It features a soft-start function; there is no shock or surge when starting or stopping the motor.

6. Low noise and no side crushing: High-precision imported smooth rods and test wheels are used for relative motion.

7. Adjustable ground pressure of the test wheel: Test wheels with ground pressure ranging from 0.5 to 1.3 MPa are available as optional accessories.

8. Convenient and user-friendly design: The test rubber wheels are automatically lifted and lowered.

Main technical parameters:

Displacement detection range: 0 to 25mm.

Deformation detection resolution: 0.01 mm.

3. Deformation detection accuracy: ±0.05 mm.

4. Temperature control range: 30 ~ 80 ℃.

5. Temperature detection resolution: 0.1 ℃.

6. Temperature control accuracy: ±0.3 ℃.

7. Ground contact pressure of the test wheel: 0.7 MPa ± 0.05 MPa.

8. Walking frequency: 42 times/min ± 1 time/min.

9. Specimen height available for testing: 30mm – 70mm

System standard configuration

1. Deformation acquisition: One channel.

2. Temperature collection: One channel.

3. Temperature control: One channel.

4. Acquisition card: One piece.

5. Printer: One.

6. Computer: One.

7 Application system software: One set.

Rated power of power supply: 380V AC, 3.5 kW; 220V AC, 500 W.

9. Main body dimensions: Length × Width × Height: 1.6m × 1.2m × 1.6m.

10. Main body weight: Net weight = 860 kg

Asphalt laboratory supporting instruments:

Automatic asphalt mixture rutting tester: ensuring road durability

The Automated Asphalt Rutting Tester is an essential tool in the field of civil engineering and road construction. This sophisticated device is designed to evaluate the resistance of asphalt mixtures to permanent deformation, commonly known as rutting. Rutting is an important factor affecting road durability as it can cause safety hazards and increase maintenance costs.

The testing process involves subjecting asphalt samples to controlled loading conditions that simulate real-world traffic scenarios. The Automated Asphalt Rutting Tester automates this process, ensuring consistent and accurate results. By applying a range of loads to the asphalt mix, the tester can measure the depth of deformation over time, providing valuable data on the material’s performance under stress.

A key benefit of using an automated asphalt rutting tester is its efficiency. Traditional testing methods are time-consuming and labor-intensive, often requiring manual intervention. In contrast, this automated system streamlines the testing process, allowing engineers to obtain results quickly and minimize human error. This efficiency is especially important in high-volume testing environments where multiple samples need to be evaluated quickly.

Additionally, the data generated by the automated asphalt rutting tester is critical to the development of high-performance asphalt mixes. By understanding how different components react to stress, engineers can optimize formulations to increase durability and reduce the likelihood of rutting. This not only extends the life of the road, but also improves driving conditions.

In summary, the automated asphalt rutting tester plays a vital role in modern road construction and maintenance. It provides accurate, automated test results that help engineers design better asphalt mixtures, ultimately creating more durable and safer roads. As the demand for high-quality infrastructure continues to grow, the importance of such testing equipment will only increase.