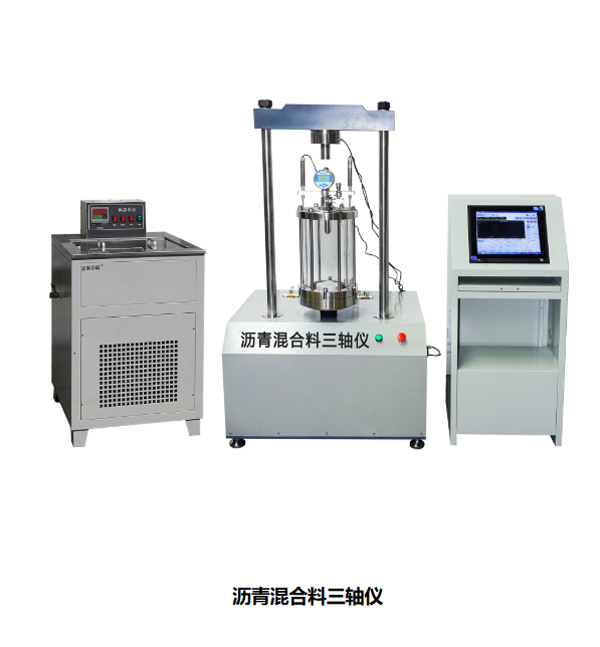

Asphalt Mixture Triaxial Tester

Asphalt Mixture Triaxial Tester

I. Introduction

This system is a triaxial compression testing device for asphalt mixtures developed based on the “Test Procedures for Asphalt and Asphalt Mixture in Highway Engineering JTG E20-2011″, utilizing stepper motor drive technology, automatic control technology, refrigeration technology, sensor technology and computer technology. It is suitable for determining the shear modulus of asphalt mixtures under specified temperature and loading conditions to evaluate the high-temperature stability of asphalt mixtures. Unless otherwise specified, the test specimens are asphalt mixture specimens with a diameter of Φ100×150mm and the test temperature is 60℃.

This system is easy to operate, has high testing accuracy and can also be used for other tests. The test process is controlled by a microcomputer.

II. Main Technical Indicators

1. The maximum rated load of the system is 100 kN.

2. The main machine stepping motor: 1000 W, 380 V × 50 Hz.

3. The confining pressure range: 0 – 3 MPa.

4. The electromagnetic heating device: heating range 0 – 100 °C, power supply 220 V × 50 Hz.

5. The external power supply for the data acquisition instrument: 220 V × 50 Hz.

6. The lifting speed range of the main machine: 0 – 50 mm/min, stepless adjustable.

7. The lifting stroke of the main machine: 0 – 100 mm.

8. The ultimate bearing pressure of the pressure chamber: 2 MPa.

9. The spoke-type pressure sensor: 0 – 100 kN, accuracy: 0.05% FS.

10. The center distance between the two columns is 420 mm.

Asphalt mixture triaxial testing machine: a key tool for pavement analysis

The asphalt mixture triaxial testing machine is an essential instrument in the field of civil engineering, especially for evaluating asphalt mixtures used in pavement construction. This advanced equipment is designed to simulate the stress and strain that asphalt pavement is subjected to under traffic loads, providing critical data for engineers and researchers.

One of the main functions of the asphalt triaxial testing machine is to evaluate the mechanical properties of asphalt mixtures. By applying controlled axial and confining pressures, the testing machine can simulate various situations in real scenarios. This allows a comprehensive analysis of the response of different asphalt mixtures under different stress levels, which is crucial for predicting their performance and durability.

The test results of the asphalt mixture triaxial testing machine can provide reference for the material selection and design of asphalt pavement. Engineers can evaluate parameters such as shear strength, modulus of resilience, and permanent deformation characteristics. This information is critical to ensure that the pavement can withstand the expected traffic loads and environmental conditions during its service life.

In addition, asphalt triaxial testing machines play an important role in quality control during the asphalt mixture production process. By testing samples from different batches, manufacturers can ensure that their products meet the required specifications and performance standards. This not only improves the quality of the road surface, but also helps to improve the overall safety and service life of road infrastructure.

In summary, the asphalt mixture triaxial testing machine is a key tool in the evaluation and design of asphalt pavement. Its ability to simulate real-world pavement conditions and provide valuable data is an essential tool for engineers working to create durable and efficient roads. As the demand for high-quality pavement continues to grow, the importance of this testing equipment will only increase in the coming years.