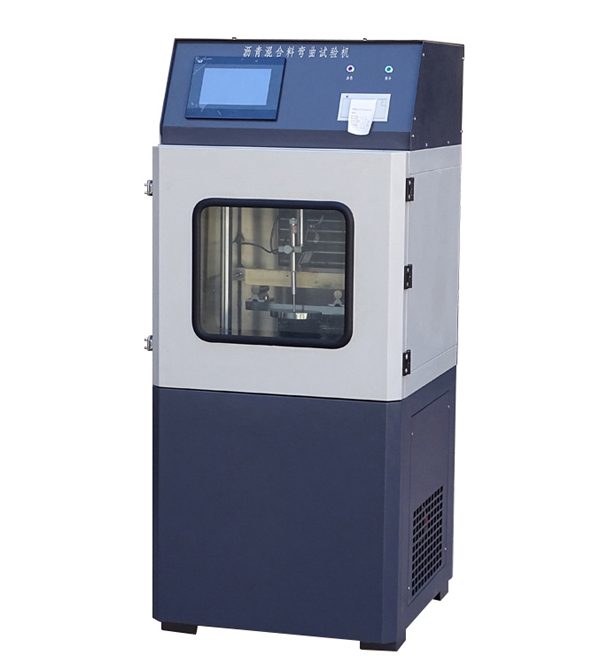

Asphalt mixture bending testing machine

Asphalt mixture bending testing machine

The asphalt mixture bending performance test system is developed in accordance with “Test Regulations for Asphalt and Asphalt Mixture in Highway Engineering JTG E20-2011″. It is driven by a stepping motor reducer, equipped with corresponding fixtures and a data acquisition and control system, and can detect the low-temperature bending and tensile tests of asphalt mixture girders. This system is composed of the main unit and corresponding fixtures, X-Y data acquisition part, microcomputer data acquisition and processing system, etc. After the specimens are clamped, the entire test process can be automated by using control. It is the first multi-functional mechanical property testing equipment for asphalt mixtures in China. It has the dual functions of a low-temperature test chamber and a low-temperature bending and tensile test device. It is an essential device for the upgrade of the new quality inspection institutions of the Ministry of Transport.

Main technical indicators

1. Stepper motor drive, with a lifting speed of 50mm/min;

Power supply: 220V×50HZ

The range of the 3-capacity grid displacement sensor: 0-15mm; Resolution: 0.01mm

4. Tensile and compressive force sensor range: 0-5KN; Accuracy: 0.05% FS

Data acquisition instrument: Power supply 220V×50HZ

Instrument dimensions (length × width × height) : 800×600×1700mm

7 Lifting stroke: 0-100mm

Temperature range: -15℃ to 60℃, accuracy 0.5℃.

Other asphalt laboratory instruments:

Asphalt mixture bending test machine: ensuring the quality and durability of road construction

The Asphalt Mixture Flexure Tester is an essential tool in the field of civil engineering, especially in road construction and maintenance. This specialized equipment is designed to evaluate the mechanical properties of asphalt mixtures, especially their flexural strength and flexibility. By simulating real working conditions, the tester provides key data to help engineers evaluate the performance of asphalt under various loads and environmental conditions.

One of the main functions of an asphalt flexure tester is to determine the stiffness and ductility of an asphalt mixture. These properties are critical to ensuring that the pavement can withstand the stresses of traffic loads and temperature fluctuations. The tester applies a controlled bending force to an asphalt mixture sample to accurately measure its response. This data is critical for engineers to design asphalt pavements that are both durable and cost-effective.

In addition, asphalt mixture bending testers play an important role in quality control during the asphalt production process. By regularly testing samples from different batches, manufacturers can ensure that their products meet the required specifications and standards. This not only helps maintain the integrity of the pavement, but also extends its service life and reduces the need for frequent repairs and maintenance.

In addition to its testing capabilities, asphalt flexure testing machines are equipped with advanced technology that makes it easy to collect and analyze data. Many modern machines come with software that can generate detailed reports, making it easier for engineers to interpret the results and make informed decisions.

In summary, the asphalt flexure tester is an important instrument in the construction industry. It can evaluate the mechanical properties of the asphalt mixture, ensuring that the road is durable and provides safe and reliable traffic for years to come. As technology continues to advance, the importance of such testing equipment will become increasingly prominent, further improving the quality of asphalt pavement around the world.